Vacuum Sealers

Countertop Chamber Vacuum Sealers

PrepRite by Everidge is the exclusive US distributor of made-in Italy Besser Vacuum products including vacuum sealers as well as storage and cooking bags. Our units are reliable tabletop machines, meeting medium to high volume portion control, product storage, and food service needs. They provide a practical and economical way of storing food in liquid, solid or cream form, extending shelf life by up to 5

times longer than conventional cooling or freezing methods.

Besser Vacuum commercial units are the perfect companion for both cook-chill systems and sous-vide cooking. They were developed in collaboration with renowned chefs and foodservice experts to offer the highest standard of vacuum technology to help extend shelf life up

to five times longer compared with conventional cook-chill methods and provide air-free packaging that protects food items and prevents freezer burn.

VACUUM SEALER HIGHLIGHTS

Vacuum Sensor

A special program that allows you to manually set

the desired vacuum percentage and obtain more

precise control of the product’s preservation cycle

due to an electronic sensor.

Additional Welding Bar

An additional sealing bar guarantees the packaging

of a larger number of bags during the same vacuum

cycle.

*Available on select models

Soft Air

An external knob that allows you to adjust the

intensity of the air return flow inside the vacuum

chamber avoiding compression of the packaged

product.

Gas flush (MAP)

A system that allows packing delicate and soft

products in a modified atmosphere (ATM).A mixture

of food gases is injected into the vacuum bag

through an external side nozzle, ensuring total

preservation of the product’s shape, consistency, and

flavor.

*Available on select models

Marinating | Infusion

A specific program that simplifies and speeds up

food marinating processes. Thanks to short and close

vacuum cycles, liquids in the bag penetrate faster

into the product’s fibers, accelerating the marinade

in a protected environment and at room

temperature.

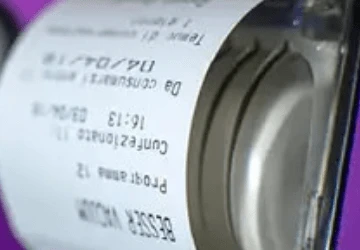

Printer | Printer Kit

A thermal printer of food labels: it simplifies the

traceability of the packaged products by printing

data relating to the packaging (product name, date

and time of packaging, product expiry, used

program, ingredients).

*Standard and/or available to add on select models

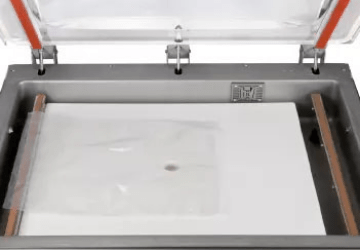

SUPERIOR QUALITY CONSTRUCTION - MADE IN ITALY

Stainless Steel Components

Body and inserts in stainless steel (Aisi 304) anti-

corrosion, transparent cover in pure polycarbonate

with a minimum thickness of 1.5 cm highly resistant,

multidirectional wheels that simplify operations of

moving and transporting.

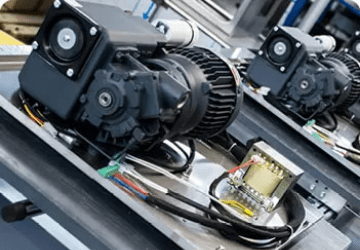

Vacuum at 99.9%

By using professional DVP and BUSCH oil pumps

equipped with gas ballast, it is possible to reach the

maximum level of vacuum allowed in a very short

time, avoiding the pump’s air condensation and its

possible damage..

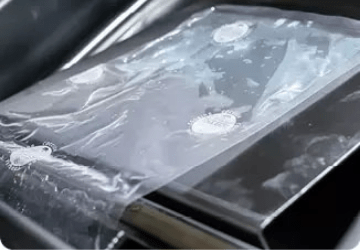

Soft Vacuum

A special program that allows the storage of liquid

and creamy products. Thanks to an intermittent

vacuum cycle, the product undergoes more delicate

stresses that prevent boiling and separation of

ingredients in the vacuum phase.

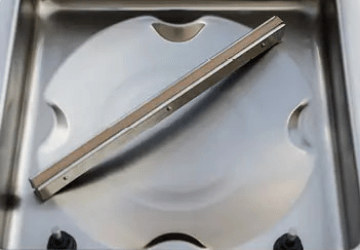

Wireless Welding Bars

Multiple wireless welding bars, equipped with

corrosion-resistant stainless steel (AISI 304) pistons

that simplify cleaning operations and guarantee total

safety during machine use, increasing the quality and

resistance of welding.

Easy cleaning

Molded and rounded stainless steel tank (AISI 304),

composed of a single thermoformed piece without

joints and weldings on the walls, expressly studied to

facilitate cleaning and hygiene operations.

Pump Maintenance

An innovative program that involves the activation of

10 consecutive cycles of vacuum that grind solid

residues left inside the pump and make the oil more

fluid. Allows reducing energy expenditure

guaranteeing automatic cleaning of the vacuum

pump.

Subscribe to the PrepRite Newsletter!

- Save Money

- Improve Food Quality & Safety

- Extend Product Shelf LIfe

Cocoa Dulce Testimonial Video